Drying tower Features

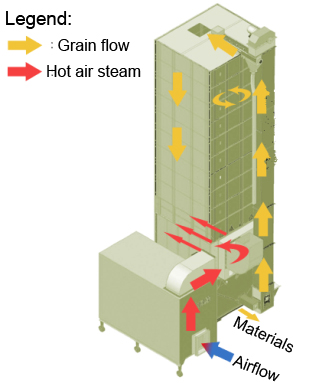

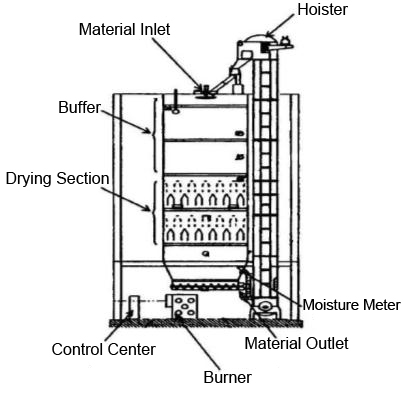

1. Advanced technology in drying industry

The dryer is designed with mixed flow drying principle, resulting in high heating efficiency, low energy consumption and large capacity. By mixed flow and low temperature drying, moisture is reduced slowly and evenly, thus damaging by heating is minimized. The grain is kept in good quality after drying with least cracking.

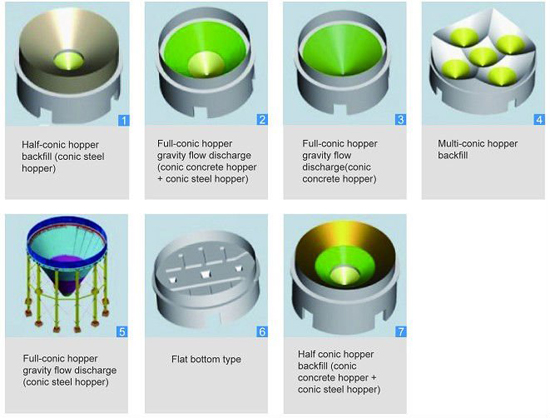

2. Patented discharge technology

The discharge is more stable, uniform, without cleaning.

3. Distinctive dust removing equipment

Muyang drying tower utilize advanced dust removing technology, which improves working environment.

4. Drying tower use galvanized sheet

With high quality anticorrosive material. Muyang drying tower has the features of stainless, abrasive resistant, anti-corrosive with nice appearance, and long life.

5. Advanced technology in drying industry

Complete NC technology in PLC screen, friendly human-computer interaction interface,safe and convenient operations.

If you also want to know more about on other projects, such as steel structure, feed mill turkey line or food processing project, you can leave your comments here, and our service will contact to you.