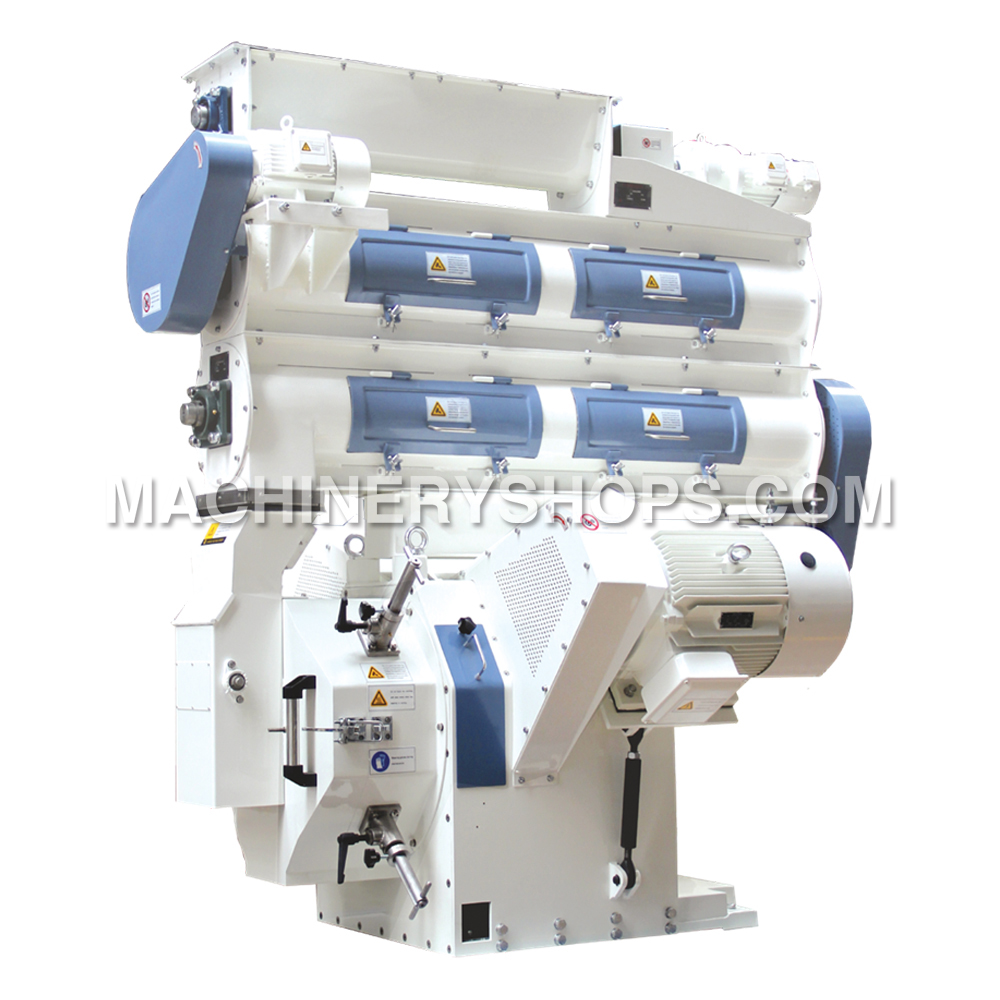

The pellet mill is directly driven by timing belt, which is characterized by its ideal drive ratio, great driving moment, smooth rotation, high throughput, low noise, easy operation and maintenance.

This type of pelleting machine can be fitted with many kinds of ring dies with φ1.5~φ12 die holes and different thickness, and the user can select based on self demand for achieving the optimum technical and economic efficiency.

This machine, characterized by its stable running performance, high throughput and high pellet forming ratio, is applicable for producing pellet feeds for livestock and poultry.

The adjustable speed control motor is adopted for feeding of this machine, and the machine is equipped with an overload protection device and an outside discharging mechanism, and the bypass gate can be opened automatically in case of overload of the main motor.

Different type of conditioners are optional as required, such as single-, double- and triple-pass conditioners as well as a double-shaft differential conditioner.

This pelleting machine is specially used for animal feed processing, generally for processing powdery, flowable and easily pelletized materials to produce pellet feeds for livestock and poultry.

Do not use it for processing food.

To ensure safety and efficiency, this machine shall be used in the areas with an altitude lower than 1000 m, a temperature from -5℃ to 40℃ and an air relative humidity from 30% to 95%.

If the area does not conform to above conditions, please indicate specially when ordering.

Thursday, October 30, 2014

Friday, September 19, 2014

The Usage on Muyang TLMC12 Jet Filter Dust Collector

Dust concentration of dust-containing air, relative humidity, physical and chemical characters of dust such as dust size, density, adhesivity and explosive repose angle shall be known after determining to use the filtering sleeve dust collector.

Consider the filtering air speed and filtering area when selecting a dust collector. The designed filtering air speed of full series dust collectors shall be not more than 4 m/min. The filtering air speed is determined by dust characteristics and density, usually the middle/lower limit is selected; as for light and small dust particles, the filtering air speed shall be much lower, or even less than 2 m/min; the lower the filtering air speed, the higher the dust removal efficiency, however, the cost will be increased; therefore, it is important to select the filtering air speed applicable for the character of dust to obtain a better performance-price ratio. Determine the filtering area based on volume of air to be treated after determining the filtering air speed; see Table 1 for corresponding parameters to select correct dust collector model.

Normally, the feed machine is used for treating dust-containing air with a dust particle size more than 1μm; for treating dust-containing air with a dust particle size less than 1μm, please inform us when ordering, so that we can select other filter material and guide you to adjust the corresponding working parameters.

Please inform us when ordering if the dust collector will be used for central dust collecting and pneumatic conveying and the air pressure exceeds 15000Pa, so that we can adjust the corresponding structure.

It is recommended to select a dust collector with larger size or equip an additional pre-purifier when the dust concentration at the entry of the dust collector is more than 15g/m3.

Please inform us if you have any special requirements to the dust collector or you have any other ideas.

In addition, we have other feed machinery available here, you can contact anytime.

Consider the filtering air speed and filtering area when selecting a dust collector. The designed filtering air speed of full series dust collectors shall be not more than 4 m/min. The filtering air speed is determined by dust characteristics and density, usually the middle/lower limit is selected; as for light and small dust particles, the filtering air speed shall be much lower, or even less than 2 m/min; the lower the filtering air speed, the higher the dust removal efficiency, however, the cost will be increased; therefore, it is important to select the filtering air speed applicable for the character of dust to obtain a better performance-price ratio. Determine the filtering area based on volume of air to be treated after determining the filtering air speed; see Table 1 for corresponding parameters to select correct dust collector model.

Normally, the feed machine is used for treating dust-containing air with a dust particle size more than 1μm; for treating dust-containing air with a dust particle size less than 1μm, please inform us when ordering, so that we can select other filter material and guide you to adjust the corresponding working parameters.

Please inform us when ordering if the dust collector will be used for central dust collecting and pneumatic conveying and the air pressure exceeds 15000Pa, so that we can adjust the corresponding structure.

It is recommended to select a dust collector with larger size or equip an additional pre-purifier when the dust concentration at the entry of the dust collector is more than 15g/m3.

Please inform us if you have any special requirements to the dust collector or you have any other ideas.

In addition, we have other feed machinery available here, you can contact anytime.

Tuesday, August 26, 2014

Hammer Tip: Go High Speed to Control Particle Size

In most cases, feed manufacturers primarily rate a hammermill's performance on its capacity to grind a certain amount of material in a given time. However, this practice ignores particle size, an important consideration in handling characteristics, pellet durability and animal performance. Traditionally, feed manufacturers who use hammermills to grind grains and other materials control particle size by changing the size of the hammermill screen holes. While screen size has a major influence on particle size, hammer tip speed is also an important factor. Generally, if all other factors are the same, hammermills with higher hammer tip speeds produce a finer grind than those with lower tip speeds.

To understand how tip speed affects particle size, it is important to know how a feed machine operates.

A hammermill grinds by two distinct forces. The first force is impact. As the grain drops into the grinding chamber, it is struck by fast moving hammers and accelerated toward the screen where a second impact occurs.

The particles that don't discharge through the screen immediately form a fluidized bed against the inside of the screen where they are ground by attrition, the second grinding force. With attrition, particles are ground as they are forced against the screen and against each other. Of the two grinding forces, impact is more efficient. Feed machinery manufacturers, therefore, have gone to great lengths to increase the amount of impact that occurs in the hammermill, resulting in steady improvements in grinding efficiency.

One way to increase the amount of impact between hammer and particle is to increase the tip speed of the hammers.

According to basic principles of physics, if motor speed is fixed, increasing the diameter of the rotor will increase the speed of the hammer tip.

Special design and material modifications are required to produce a machine that operates safely at rotation speeds of more than 25,000 feet per minute. The rotor shaft and plates are manufactured from materials that withstand tremendous forces. The assembly is balanced to prevent excessive vibration. Engineers and designers must also give consideration to the bearing mounts, hammermill base and frame to maintain proper alignment and support for the heavy rotor assembly. A hammermill with a higher tip speed will produce a finer grind than one with a slower tip speed, provided the two grinders have the same size screen. If a high-speed hammermill is equipped with a larger hole screen, ground material particle size will be the same for both machines.

To understand how tip speed affects particle size, it is important to know how a feed machine operates.

A hammermill grinds by two distinct forces. The first force is impact. As the grain drops into the grinding chamber, it is struck by fast moving hammers and accelerated toward the screen where a second impact occurs.

The particles that don't discharge through the screen immediately form a fluidized bed against the inside of the screen where they are ground by attrition, the second grinding force. With attrition, particles are ground as they are forced against the screen and against each other. Of the two grinding forces, impact is more efficient. Feed machinery manufacturers, therefore, have gone to great lengths to increase the amount of impact that occurs in the hammermill, resulting in steady improvements in grinding efficiency.

One way to increase the amount of impact between hammer and particle is to increase the tip speed of the hammers.

According to basic principles of physics, if motor speed is fixed, increasing the diameter of the rotor will increase the speed of the hammer tip.

Special design and material modifications are required to produce a machine that operates safely at rotation speeds of more than 25,000 feet per minute. The rotor shaft and plates are manufactured from materials that withstand tremendous forces. The assembly is balanced to prevent excessive vibration. Engineers and designers must also give consideration to the bearing mounts, hammermill base and frame to maintain proper alignment and support for the heavy rotor assembly. A hammermill with a higher tip speed will produce a finer grind than one with a slower tip speed, provided the two grinders have the same size screen. If a high-speed hammermill is equipped with a larger hole screen, ground material particle size will be the same for both machines.

Wednesday, August 20, 2014

Installation of the Sifter

There are two ways to install Muyang SFJH series Rota-shake Sifters: support base type and suspension type. For support base type installation, the stander of the sifter is directly installed on foundation throught anchor bolts, while suspension type installation is without stander and hanging mechanism, the carrier of the sifter can be directly suspended on the roof of the factory building throught wire ropes; however, there are certain requirements to the installation site and the factory building.

This feed machine leaves the factory as a whole and usually applies support base type installation. Before installation, check against the dimensions in the sample diagram of equipment for enough space, especially the space for operation, maintenance and accessory replacement. To ensure the stability of stationariness, installation site of the sifter shall be solid and horizontal. Meanwhile, material weight in the sifter shall be considered in calculation. The base of sifter shall be connected with the foundation through anchor bolts tightly to prevent the sifter from offset during running.

If suspension installation is applied, it is suggested to assemble the four wire ropes with turnbuckles so as to level the carrier of the sifter. Meanwhile, protection device must be used to protect the sifter when any of the wire ropes is broken.

This feed machine leaves the factory as a whole and usually applies support base type installation. Before installation, check against the dimensions in the sample diagram of equipment for enough space, especially the space for operation, maintenance and accessory replacement. To ensure the stability of stationariness, installation site of the sifter shall be solid and horizontal. Meanwhile, material weight in the sifter shall be considered in calculation. The base of sifter shall be connected with the foundation through anchor bolts tightly to prevent the sifter from offset during running.

If suspension installation is applied, it is suggested to assemble the four wire ropes with turnbuckles so as to level the carrier of the sifter. Meanwhile, protection device must be used to protect the sifter when any of the wire ropes is broken.

Friday, August 8, 2014

SYPZ Type Vacuum Coating System

SYPZ type vacuum coating system is arranged behind pelleting and extruding, and suitable for pellets to be coated with the liquids in large proportion like oil, enzyme preparation, vitamin, antioxidant and amino acid etc. It is also applicable for the pellets with high density, of which the coating rate is low but the coating effect is not good for common pellet surface.

A vacuum liquid coater of the SYPZ series is automatically controlled by a computer with a few operating parameters. It is only necessary to input the output-to-oil ratio, the system will run automatically, so the operation is very convenient. The coater features high accuracy of coating proportion and capacity, and with excellent coating evenness. And the feed machine is characterized by its favorable vacuum degree and vacuum retention.

The sprayed liquid will be fully absorbed under the vacuum condition.

The spraying ratio can reach more than 35 percent.

The spraying accuracy can reach 3 millesimal.

With automatic control system, easy to operate and maintain.

Widely used for spraying the liquid and oil to the extrusion feed and pellet feed.

A vacuum liquid coater of the SYPZ series is automatically controlled by a computer with a few operating parameters. It is only necessary to input the output-to-oil ratio, the system will run automatically, so the operation is very convenient. The coater features high accuracy of coating proportion and capacity, and with excellent coating evenness. And the feed machine is characterized by its favorable vacuum degree and vacuum retention.

The sprayed liquid will be fully absorbed under the vacuum condition.

The spraying ratio can reach more than 35 percent.

The spraying accuracy can reach 3 millesimal.

With automatic control system, easy to operate and maintain.

Widely used for spraying the liquid and oil to the extrusion feed and pellet feed.

Wednesday, July 30, 2014

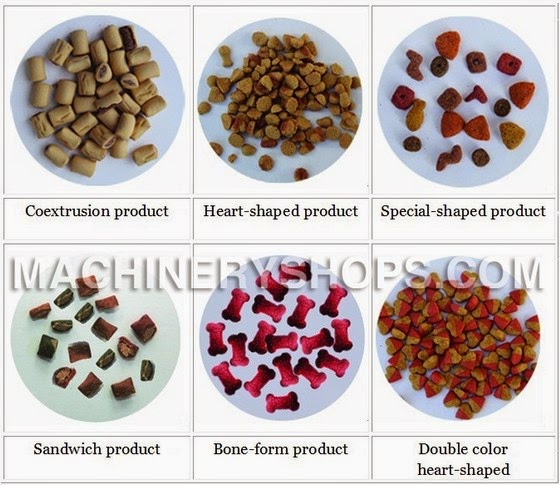

FAMSUN Dry Petfoods Factory Project

FAMSUN Dry Petfoods Factory Project

--Helping pets live longer, healthier lives through sound nutrition

The trends of humanization of pets, however, has put the flavor, color and shape of petfoods even the aesthetic quality of package in the most important position of pet owner's consumption decision. To be competitive in the high-end market, petfood manufacturer must make its products distinguished.

As a professional and experienced technical supplier, FAMSUN is well prepared to work with pet feed machinery manufacturers to developed their own high-value, nutritional, attractive petfood products. FAMSUN innovative extrusion system and post treatment processes, state-of-the-art processing techniques, as well as customized solutions enable customers to produce various high-end competitive products their own.

Friday, July 25, 2014

Pelletizing Process on Pellet Mill

Startup a new pellet mill or a pellet mill with a new ring die according to following steps:

1) Open the bypass gate;

2) Startup the main motors of the pellet mill. The motor shall be started up in Y firstly, and runs in delta connection while under normal operation speed;

3) Feed a certain amount of oily coarse mash to the inlet of the feed machine manually, and continue feeding until pellet is formed. This is the primary lubrication for the ring die before normal production;

Oil bearing material: generally, feed mash with ≥10% oil content. The raw materials of rice bran, expanding soybean and others can also used as oil bearing material. As for bad quality ring die with rough hole wall, about 15% spun yarn passing through 40 mesh screen can be added in oil bearing material for rinsing and grinding the die (generally persist for more than 30 minutes), otherwise, the materials cannot be discharged.

4) Startup the conditioner motor;

5) Startup the feeder motor, adjust the frequency converter to a low frequency (generally about 5Hz) and allow the feed to enter the conditioner slowly, Do not add any steam at the beginning of pelletizing, close the bypass gate and slowly quicken the feeding speed based on the current of the main motor;

6) Open the steam valve a bit, then increase the feeding amount when the ammeter’s pointer is falling; when the ammeter’s pointer of the main motor reaches the normal load, add steam amount to allow the ammeter’s pointer to fall back. Repeat again and again until the maximum output and the best quality of pellet are obtained under the rated load;

7) A schematic diagram of pellet extrusion is shown in Fig 4.1. The feeding amount and steam supply are different upon the types of ring die and formulas, and the pellet quality varies as well. So the operator shall be rich in operating experience.

1) Open the bypass gate;

2) Startup the main motors of the pellet mill. The motor shall be started up in Y firstly, and runs in delta connection while under normal operation speed;

3) Feed a certain amount of oily coarse mash to the inlet of the feed machine manually, and continue feeding until pellet is formed. This is the primary lubrication for the ring die before normal production;

Oil bearing material: generally, feed mash with ≥10% oil content. The raw materials of rice bran, expanding soybean and others can also used as oil bearing material. As for bad quality ring die with rough hole wall, about 15% spun yarn passing through 40 mesh screen can be added in oil bearing material for rinsing and grinding the die (generally persist for more than 30 minutes), otherwise, the materials cannot be discharged.

4) Startup the conditioner motor;

5) Startup the feeder motor, adjust the frequency converter to a low frequency (generally about 5Hz) and allow the feed to enter the conditioner slowly, Do not add any steam at the beginning of pelletizing, close the bypass gate and slowly quicken the feeding speed based on the current of the main motor;

6) Open the steam valve a bit, then increase the feeding amount when the ammeter’s pointer is falling; when the ammeter’s pointer of the main motor reaches the normal load, add steam amount to allow the ammeter’s pointer to fall back. Repeat again and again until the maximum output and the best quality of pellet are obtained under the rated load;

7) A schematic diagram of pellet extrusion is shown in Fig 4.1. The feeding amount and steam supply are different upon the types of ring die and formulas, and the pellet quality varies as well. So the operator shall be rich in operating experience.

Thursday, July 17, 2014

Muyang Biomass Engineering: Wood and woody residues

***Muyang Biomass Engineering: Wood and woody residues***

--Making a substantial contribution to global energy security

Woody biomass from forests remains the largest biomass energy source today. Examples include trees, trees removals, prunnings, stumps, yard clippings, and wood manufacturing residues such as sawdust, bark, culled wood, etc. Made from renewable forest byproducts and of high heating value, wood pellets provide a renewable, sustainable fuel source for energy industry to enjoy.

--Making a substantial contribution to global energy security

Woody biomass from forests remains the largest biomass energy source today. Examples include trees, trees removals, prunnings, stumps, yard clippings, and wood manufacturing residues such as sawdust, bark, culled wood, etc. Made from renewable forest byproducts and of high heating value, wood pellets provide a renewable, sustainable fuel source for energy industry to enjoy.

Wednesday, July 9, 2014

Muyang Steel Silo---Supportive along the grain value chain

We offer products and complete solutions in the field of grain handling, cleaning, drying and storage for agribusiness section. There are now over 1000 Muyang steel silo projects standing around the world and making their efforts to the global food security, from grain collection points to grain elevators, from inland/water terminals to processing plants such as feed mills, rice mills, flour mills, breweries, oilseed processing factories, etc.

The key products and systems include:

1.Assembly type steel silos: 1~18,000 t/silo; Spiral steel silos,1-8,000 t/silo;

2.Material handling system: bucket elevators, conveyors, sweepers, spreaders, etc.;

3.Conditioning and drying systems: cleaners, dust collectors, dumping systems, dryers, fans, controls, etc.

The key products and systems include:

1.Assembly type steel silos: 1~18,000 t/silo; Spiral steel silos,1-8,000 t/silo;

2.Material handling system: bucket elevators, conveyors, sweepers, spreaders, etc.;

3.Conditioning and drying systems: cleaners, dust collectors, dumping systems, dryers, fans, controls, etc.

Tuesday, June 24, 2014

Muyang Grinder Machine

The machine is developed with the method of mixed powder jerring,which is widely applied for the mate ria grnding for the trades of pharmaceutics chemical and foodstuff etc.

The feed machine has a simple structure and is easy to be installed and dismantled and cleaned,with the featu res of stable running,convenient moving low noise and high grinding effi-ciency.etc.

The machine is a high speed running one The target material is smashed by the cutting and rinding of high-speed knives,of which the figure and size of knives can be selected in accordance with different materials and the size of granules can be acqui red by changing of the screen and regulating the soeed.

The feed machine has a simple structure and is easy to be installed and dismantled and cleaned,with the featu res of stable running,convenient moving low noise and high grinding effi-ciency.etc.

The machine is a high speed running one The target material is smashed by the cutting and rinding of high-speed knives,of which the figure and size of knives can be selected in accordance with different materials and the size of granules can be acqui red by changing of the screen and regulating the soeed.

Thursday, June 19, 2014

Four Sizes Produced by Extruder Machine

There are four conditions, under any of which pellets of non-uniform sizes will be produced:

1) Feed mash and water added into the conditioner cannot be evenly mixed with each other because water added into the conditioner is not sufficiently atomized. In this case, the water atomizing nozzle should be checked and cleaned thoroughly to make it free of any blockage.

2) Die holes blocked by large ground particles or foreign matters (usually are accumulated residues), especially when extruding small pellets. Production problems in this case are easy to be identified. The finished pellets usually are uniform at the beginning of production, but this performance cannot sustain for a long time and pellets in large size and small size generated. In this case, it has to stop the feed machine to clean the die holes. In order to avoid die hole blockage, the ground particle size of raw material should not exceed 1/3 of the die hole.

3) Screw is worn out and end of life. This situation can be identified through the clearance between chamber inner wall and screw flight profile. The normal clearance is 1.5mm-2.0mm. When it larger than 5mm, pellets in different sizes are produced. In this case, it is necessary to replace the worn screw with a new one.

4) Feed flow unevenly distributed to discharge at Venture tube because of severe wearing loss of the distributing cone. In this case, the distributing cone should be replaced with a new one.

1) Feed mash and water added into the conditioner cannot be evenly mixed with each other because water added into the conditioner is not sufficiently atomized. In this case, the water atomizing nozzle should be checked and cleaned thoroughly to make it free of any blockage.

2) Die holes blocked by large ground particles or foreign matters (usually are accumulated residues), especially when extruding small pellets. Production problems in this case are easy to be identified. The finished pellets usually are uniform at the beginning of production, but this performance cannot sustain for a long time and pellets in large size and small size generated. In this case, it has to stop the feed machine to clean the die holes. In order to avoid die hole blockage, the ground particle size of raw material should not exceed 1/3 of the die hole.

3) Screw is worn out and end of life. This situation can be identified through the clearance between chamber inner wall and screw flight profile. The normal clearance is 1.5mm-2.0mm. When it larger than 5mm, pellets in different sizes are produced. In this case, it is necessary to replace the worn screw with a new one.

4) Feed flow unevenly distributed to discharge at Venture tube because of severe wearing loss of the distributing cone. In this case, the distributing cone should be replaced with a new one.

Thursday, June 12, 2014

Muyang Introduced a New Grain Drying Storage System

Recently, Muyang developed and produced grain drying equipments drawing on seasonal characteristics in different regions of the South and the North's grain harvest.

Its use of simulation design and CNC machining tools, set intelligent control technology, variable temperature drying process, Francis and shun reflux, positive and negative, continuous and cyclic drying technologies combine in one, effectively ensure the whole grain drying automated process, low energy consumption, improve the quality of grain drying, to reduce the loss of grain postpartum, energy conservation, technology reached the international advanced level.

Meanwhile, Muyang adopted steel instead of traditional concrete in grain storage silo. Because the silo is clean, and its good sealing can avoid rodents, effectively reducing the proportion of losses during storage of up to 5%.

Currently, Muyang grain drying and storage system have been in the major grain-producing provinces such as Anhui, Jiangsu, Hubei, northeast provinces and other places to establish a demonstration line, after using the system to meet the needs, easy operation, high level of intelligence, low energy consumption, high combustion efficiency of new heat source, and the remaining heat recovery saves energy, food quality and good after drying, become suitable for food production in the status quo of China's low-carbon smart shelf impairment drying and storage equipment.

President Fan of Muyang introduced that grain drying and storage projects as planned popularize annually 2.7 million tons of grain drying; there is no reasonable food store, it will have at least 5% loss, loss of 135,000 tons of grain per year; drying reasonable scientific handling and storage, representing an increase of 135,000 tons of grain annually. 2020, a year due to increased drying and storage devices can be increased 3.78 million tons of grain.

Muyang now has cooprations with a number of economies in the Asia-Pacific international cooperation in grain cultivation, logistics, processing and other aspects of development of agricultural science and technology cooperation, high-tech and export of agricultural products.

Its use of simulation design and CNC machining tools, set intelligent control technology, variable temperature drying process, Francis and shun reflux, positive and negative, continuous and cyclic drying technologies combine in one, effectively ensure the whole grain drying automated process, low energy consumption, improve the quality of grain drying, to reduce the loss of grain postpartum, energy conservation, technology reached the international advanced level.

Meanwhile, Muyang adopted steel instead of traditional concrete in grain storage silo. Because the silo is clean, and its good sealing can avoid rodents, effectively reducing the proportion of losses during storage of up to 5%.

Currently, Muyang grain drying and storage system have been in the major grain-producing provinces such as Anhui, Jiangsu, Hubei, northeast provinces and other places to establish a demonstration line, after using the system to meet the needs, easy operation, high level of intelligence, low energy consumption, high combustion efficiency of new heat source, and the remaining heat recovery saves energy, food quality and good after drying, become suitable for food production in the status quo of China's low-carbon smart shelf impairment drying and storage equipment.

President Fan of Muyang introduced that grain drying and storage projects as planned popularize annually 2.7 million tons of grain drying; there is no reasonable food store, it will have at least 5% loss, loss of 135,000 tons of grain per year; drying reasonable scientific handling and storage, representing an increase of 135,000 tons of grain annually. 2020, a year due to increased drying and storage devices can be increased 3.78 million tons of grain.

Muyang now has cooprations with a number of economies in the Asia-Pacific international cooperation in grain cultivation, logistics, processing and other aspects of development of agricultural science and technology cooperation, high-tech and export of agricultural products.

Thursday, June 5, 2014

Steel Silo Industry Success Stories

Muyang has over 40 years of experience and silo engineering expertise, specializing in material storage technology research and development, design, installation and services, and its products in the domestic occupies about nearly 40% for market share, is by far the most full-scale Asian service providers with most comprehensive single largest storage capacity.

Muyang silo introduces the latest technology and equipment in the world with many customers around the world of design and construction of more than 5,000 spiral steel silos, corrugated steel silo fabricated insulation warehouse project. Muyang spiral steel silo for the introduction of a full set of equipment and technology in Europe, to provide from 50 to 7000 tons of different specifications of the flat for the user, cone bottom, the flow of the material, the material porous materials, such as different forms of steel silos; bellows assembly type steel silo for the United States to introduce the latest manufacturing technology and equipment, with the most advanced computer system that provides users with 10 to 16,800 tons of different specifications of the flat, conical bottom, the flow of the material, the material porous materials, such as different forms of steel silos. Muyang provides customers include and upgrade from technology, civil engineering design, automation and control systems, transportation, cleaning, manufacturing magnetic separation, metering, drying, fumigation, refrigeration, ventilation, dust, temperature, humidity and other measuring equipment, installation, commissioning and training of personnel stop turnkey projects. Muyang fabricated steel silo, spiral steel silo, warehouse and other insulation products are widely used in food, oil, ports, corn deep processing, flour, brewing, chemical, feed, building materials and environmental protection industries in more than twenty provinces, municipalities, autonomous regions and municipalities of more than 1,000 seats built warehousing projects , selling Egypt, Saudi Arabia, Iran , Thailand, India, Japan, the United States, Malaysia, the world's nearly 100 countries and regions, to promote Chinese steel silo industry to the world. Famous customers include Louis Dreyfus, grain storage, COFCO, grain and oil in the sea, 93 Oil Group, DBN Grou , Tangrenshen Group, Yanjing Beer, Snow Beer, Suntory, Tsingtao Beer, Yi Hai, Jiangsu Jianghai, Xiwang Group, chrysanthemum MSG, etc. ; overseas customers such as Taiwan Dacheng, Thailand Chia Tai Group, CJ and so on.

Muyang silo introduces the latest technology and equipment in the world with many customers around the world of design and construction of more than 5,000 spiral steel silos, corrugated steel silo fabricated insulation warehouse project. Muyang spiral steel silo for the introduction of a full set of equipment and technology in Europe, to provide from 50 to 7000 tons of different specifications of the flat for the user, cone bottom, the flow of the material, the material porous materials, such as different forms of steel silos; bellows assembly type steel silo for the United States to introduce the latest manufacturing technology and equipment, with the most advanced computer system that provides users with 10 to 16,800 tons of different specifications of the flat, conical bottom, the flow of the material, the material porous materials, such as different forms of steel silos. Muyang provides customers include and upgrade from technology, civil engineering design, automation and control systems, transportation, cleaning, manufacturing magnetic separation, metering, drying, fumigation, refrigeration, ventilation, dust, temperature, humidity and other measuring equipment, installation, commissioning and training of personnel stop turnkey projects. Muyang fabricated steel silo, spiral steel silo, warehouse and other insulation products are widely used in food, oil, ports, corn deep processing, flour, brewing, chemical, feed, building materials and environmental protection industries in more than twenty provinces, municipalities, autonomous regions and municipalities of more than 1,000 seats built warehousing projects , selling Egypt, Saudi Arabia, Iran , Thailand, India, Japan, the United States, Malaysia, the world's nearly 100 countries and regions, to promote Chinese steel silo industry to the world. Famous customers include Louis Dreyfus, grain storage, COFCO, grain and oil in the sea, 93 Oil Group, DBN Grou , Tangrenshen Group, Yanjing Beer, Snow Beer, Suntory, Tsingtao Beer, Yi Hai, Jiangsu Jianghai, Xiwang Group, chrysanthemum MSG, etc. ; overseas customers such as Taiwan Dacheng, Thailand Chia Tai Group, CJ and so on.

Thursday, May 29, 2014

Muyang - Largest Feed Machinery Manufacture

Muyang feed machinery has been in operation for nearly 50 years now, specializing in the manufacturing and design of feed production lines and related machinery, suitable for use in poultry feed, stock feed, aquatic feed and feed additive factories.

Muyang has successfully continued to grow year after year and strived to be the most innovative in our field, constantly trying to find ways to innovate and improve products to meet the changing demands of our customers. Painstaking attention is paid to the design and production of our lines, meaning our products are all of the highest quality, while at the same time being competitively priced.

Currently, Muyang has multiple R & D centers and testing centers in Asia, Europe and America with world's most powerful international R & D team in the industry. Having developed over 200 series (more than 1000 models) of high quality machines, Muyang has the global advanced “turnkey” engineering service capability and rich experience in various types of feed production lines from common livestock&poultry feed to high-grade aquatic extruded feed, grain processing lines, edible oil, brewing, powder, storage and biomass energy. Muyang’s products are well sold in more than 80 countries and regions and the majority of the top 100 enterprises in the industry has become Muyang’s customer.

Muyang has successfully continued to grow year after year and strived to be the most innovative in our field, constantly trying to find ways to innovate and improve products to meet the changing demands of our customers. Painstaking attention is paid to the design and production of our lines, meaning our products are all of the highest quality, while at the same time being competitively priced.

Currently, Muyang has multiple R & D centers and testing centers in Asia, Europe and America with world's most powerful international R & D team in the industry. Having developed over 200 series (more than 1000 models) of high quality machines, Muyang has the global advanced “turnkey” engineering service capability and rich experience in various types of feed production lines from common livestock&poultry feed to high-grade aquatic extruded feed, grain processing lines, edible oil, brewing, powder, storage and biomass energy. Muyang’s products are well sold in more than 80 countries and regions and the majority of the top 100 enterprises in the industry has become Muyang’s customer.

Thursday, May 8, 2014

Muyang Attend 2013 International Silo Technology Exhibition

From June 25th 2013 to June 27th , 2013 China International silo technology and equipment exhibition was held in Shanghai Everbright Convention & Exhibition Center by the China Association of Ports and Transport Branch, and Muyang was involved in this event.

During the exhibition, China Ports Association president visited the exhibition and Ding Keyi guided and cordial conversation with Mr. Sun Xuqing from Muyang Engineering Division, and he made fully affirmed on Muyang’s outstanding contribution.

Silo in the 1980s to enter China, the development in the country more than 100 years of history, the unprecedented rapid development. Currently, the Muyang grain silo business covers a number of areas, oil, ports, food, brewing, feed, building materials and so on. In a large silo works, Muyang has for many years become the frontrunner position in tons, with most of the five industries: "China port industry jiancang Up" "warehouse type Max has assembled position, screw positions, holding positions." "storage capacity specifications of the most comprehensive, from 50 tons to 16,500 tons, "" leading technology, using finite element analysis to ensure the most secure and reliable silo "," silo-type maximum, the strongest supporting steel structure design, "In addition, Muyang steel silo can be broken down with the feed system, silo feed anti-grading system, and with independent property rights clearance machine.

It is understood that Muyang has become the world's leading storage system solutions for service providers to have enough confidence.

The exhibition, portable storage elements Muyang Front Desk, 140 air transport conveyor, storage proportional model, corporate promotional video, warehousing engineering 3D animation, an appearance attracted many customers come to visit, advice and posed for pictures. Warehousing model on display examples of Egyptian project, the project stored material is corn, the total storage capacity reached 30000t. Process systems including feeding, conveying, cleaning, dusting, drying, storage, ventilation, temperature, level, steel systems, car payment systems, pour warehouse systems. According to this model, on-site customers can clearly understand the whole process materials warehouse.

In addition, Muyang is also a major highlight of transport exhibition on the development of the company sent 140 air conveyor, the device uses a first-class coating process, streamlined design, rugged, beautiful, and durable; low overall device throughput, energy , good sealing, easy green, maintenance, and configuration deviation, stop, speed, blockades and other security monitoring devices, the use of safer, this conveyor is widely used in food, ports, terminals, mining, coal, chemical, steel and other industries.

The three-day exhibition, Muyang showed its advanced equipment, as well as with Project staff attentive powerful persuasive explanations, showed their strength in the storage industry leader, attracting a large number of customer focus, has won industry competitors polite, and establish a Muyang our brand image, warehousing shepherd to the world, leading the development of the industry has taken a solid step forward.

During the exhibition, China Ports Association president visited the exhibition and Ding Keyi guided and cordial conversation with Mr. Sun Xuqing from Muyang Engineering Division, and he made fully affirmed on Muyang’s outstanding contribution.

Silo in the 1980s to enter China, the development in the country more than 100 years of history, the unprecedented rapid development. Currently, the Muyang grain silo business covers a number of areas, oil, ports, food, brewing, feed, building materials and so on. In a large silo works, Muyang has for many years become the frontrunner position in tons, with most of the five industries: "China port industry jiancang Up" "warehouse type Max has assembled position, screw positions, holding positions." "storage capacity specifications of the most comprehensive, from 50 tons to 16,500 tons, "" leading technology, using finite element analysis to ensure the most secure and reliable silo "," silo-type maximum, the strongest supporting steel structure design, "In addition, Muyang steel silo can be broken down with the feed system, silo feed anti-grading system, and with independent property rights clearance machine.

It is understood that Muyang has become the world's leading storage system solutions for service providers to have enough confidence.

The exhibition, portable storage elements Muyang Front Desk, 140 air transport conveyor, storage proportional model, corporate promotional video, warehousing engineering 3D animation, an appearance attracted many customers come to visit, advice and posed for pictures. Warehousing model on display examples of Egyptian project, the project stored material is corn, the total storage capacity reached 30000t. Process systems including feeding, conveying, cleaning, dusting, drying, storage, ventilation, temperature, level, steel systems, car payment systems, pour warehouse systems. According to this model, on-site customers can clearly understand the whole process materials warehouse.

In addition, Muyang is also a major highlight of transport exhibition on the development of the company sent 140 air conveyor, the device uses a first-class coating process, streamlined design, rugged, beautiful, and durable; low overall device throughput, energy , good sealing, easy green, maintenance, and configuration deviation, stop, speed, blockades and other security monitoring devices, the use of safer, this conveyor is widely used in food, ports, terminals, mining, coal, chemical, steel and other industries.

The three-day exhibition, Muyang showed its advanced equipment, as well as with Project staff attentive powerful persuasive explanations, showed their strength in the storage industry leader, attracting a large number of customer focus, has won industry competitors polite, and establish a Muyang our brand image, warehousing shepherd to the world, leading the development of the industry has taken a solid step forward.

Friday, April 25, 2014

Muyang and Muyang Vision

Muyang is specialized in manufacturing feed machinery, food processing machinery, bio-energy equipments and Installation for complete engineering, which has passed the certification of ISO9001:2000 and CE. Our products are widely used in various fields such as grain, feed, husbandry, aquaculture farm and environment friendly industry.

Depend on the state of the art technology in our field and mature business administration systems, which make the products of Muyang not only sold well in domestic, market, but also have been exported to European, African and other countries. Our feed complete equipments for poultry, livestock and aquaculture are on top of the products which are exported to abroad. Our products are titled the honor as "China Famous Brand", "China Superior Product ", "Trust worthy for Quality in China" and "Qualified Company for Quality Supervision".

Taking "Sincerity makes trust, Quality wins market" as our business philosophy, by our advanced know how, superior quality and satisfactory services, we have gained the trust of our customers. We also have acquired plentiful and excellent practical experiences in feed complete engineering, grain conveying engineering, microbial environment friendly engineering and storage engineering. By our scientific design, excellent technology, fine product, thoughtful and perfect service, we wish to join hands with our customers, advance together and cooperate sincerely, so as to create a brilliant future.

Depend on the state of the art technology in our field and mature business administration systems, which make the products of Muyang not only sold well in domestic, market, but also have been exported to European, African and other countries. Our feed complete equipments for poultry, livestock and aquaculture are on top of the products which are exported to abroad. Our products are titled the honor as "China Famous Brand", "China Superior Product ", "Trust worthy for Quality in China" and "Qualified Company for Quality Supervision".

Taking "Sincerity makes trust, Quality wins market" as our business philosophy, by our advanced know how, superior quality and satisfactory services, we have gained the trust of our customers. We also have acquired plentiful and excellent practical experiences in feed complete engineering, grain conveying engineering, microbial environment friendly engineering and storage engineering. By our scientific design, excellent technology, fine product, thoughtful and perfect service, we wish to join hands with our customers, advance together and cooperate sincerely, so as to create a brilliant future.

Wednesday, April 16, 2014

Muyang --- Innovation Is : innovation is the First Productive Force

In the field of feed machinery, Chinese companies have been exploring innovative and unique way. One of them is Muyang, a typicl industry of that way, has been translated from a local company into a leader enterprise.

Feed machinery industry, as one of the basic industries of the national economy, is highly concerned. The downtrun of economy in 2013 on didn’t influence feed machinery industry greatly, but feed machinery industry was still going through an adjustment, so it is a key point whether the industry could do and adhere to innovation or not.

Currently, among the top 10 feed machinery suppliers, eight companies have established good relations with Muyang. Now, Chinese feed industry ranked in the top 30 corporate giants have become Muyang’s major customers. Muyang now globally hires dozens of foreign experts and more than 50 agents, among which there are many top 500 companies worldwide which helps Muyang to open up a wider road.

Muyang's President, Fan says that innovation would always be the core competency in feed machinery industry. As the rapid growth of the city, and the high feed processing technology on raising, aquaculture and animal nutrition, feed machinery industry would face more new challenges and further opportunities, so innovation is Muyang’s fist vitality.

Feed machinery industry, as one of the basic industries of the national economy, is highly concerned. The downtrun of economy in 2013 on didn’t influence feed machinery industry greatly, but feed machinery industry was still going through an adjustment, so it is a key point whether the industry could do and adhere to innovation or not.

Currently, among the top 10 feed machinery suppliers, eight companies have established good relations with Muyang. Now, Chinese feed industry ranked in the top 30 corporate giants have become Muyang’s major customers. Muyang now globally hires dozens of foreign experts and more than 50 agents, among which there are many top 500 companies worldwide which helps Muyang to open up a wider road.

Muyang's President, Fan says that innovation would always be the core competency in feed machinery industry. As the rapid growth of the city, and the high feed processing technology on raising, aquaculture and animal nutrition, feed machinery industry would face more new challenges and further opportunities, so innovation is Muyang’s fist vitality.

Wednesday, April 2, 2014

Muyang Pet Food Twin Screw Extruder

Now, most Chinese technology of extruders derives from abroad and the technology is mainly applied for the fields of plastic grease and food processing while it has not been heavily used in pet food processing. While Muyang pet food twin screw extruder is made and designed by Muyang research team for many years' study, and it has completed successfully over 3000 various animal and food construction engineering all over the world.

Muyang professional installation team, after experiencing numerous hardships and tests, always coordinate allocation of quality installation and construction period and ensure the shortest constrution duration on the basis of excellent design which is able to produce pellet of granularity <1.0mm and it is suitable for materials (oil content more than 17%,up to 25% for maximum; meat content up to 35% for maximum). The products through the machine feature good quality and great appearance.

When people are choosing their extruding machines, the most important thing they care is how to ensure the uniformity of material shape. The population of the machine is that it can greatly improve the shapes of the finished products. Its steady state of screw structure helps to enhance ripening uniformity of materials in the screw and its fully intermeshing twin-screw extruder of zero gap contributes to effectively controlling the shearing, so as to ensure consistent the pellet expansion coefficient and ripening time of all materials in the extruding barrel. The patent structure of steady outflow of feeding device and double-mold technology can effectively ensure consistent each point of the material flow rate and extruded pellet uniform in length.

Muyang professional installation team, after experiencing numerous hardships and tests, always coordinate allocation of quality installation and construction period and ensure the shortest constrution duration on the basis of excellent design which is able to produce pellet of granularity <1.0mm and it is suitable for materials (oil content more than 17%,up to 25% for maximum; meat content up to 35% for maximum). The products through the machine feature good quality and great appearance.

When people are choosing their extruding machines, the most important thing they care is how to ensure the uniformity of material shape. The population of the machine is that it can greatly improve the shapes of the finished products. Its steady state of screw structure helps to enhance ripening uniformity of materials in the screw and its fully intermeshing twin-screw extruder of zero gap contributes to effectively controlling the shearing, so as to ensure consistent the pellet expansion coefficient and ripening time of all materials in the extruding barrel. The patent structure of steady outflow of feeding device and double-mold technology can effectively ensure consistent each point of the material flow rate and extruded pellet uniform in length.

Tuesday, March 18, 2014

Muyang Drying Technology

Muyang drying technology is derived from 1999, and won honorary title such as the second prize of National Scientific and Technological Progress Award and China Innovative Products. Muyang drying equipments are sold well to China, Ukraine, Indonesia, Bangladesh, Congo, Mozambique, Angola and other countries and regions. Muyang successfully undertook drying construction projects of strategic grain reserve for grain reserve depot, transit store of China provinces and China's grain storage management corporation. Muyang is gradually becoming the world's leading grain drying engineering service providers.

Muyang drying engineering provides all-round value-added services

(1) Consultative full services from planning, civil engineering, technology, manufacturing, installation and training;

(2) Preservation drying of corn, rice, wheat, soybean, peanut to low temperature drying of seeds;

(3) From harvest agricultural machinery, wet grain cleaning, transportation, bin before(after) drying, automation and control systems to dust settling system.

Muyang drying engineering provides all-round value-added services

(1) Consultative full services from planning, civil engineering, technology, manufacturing, installation and training;

(2) Preservation drying of corn, rice, wheat, soybean, peanut to low temperature drying of seeds;

(3) From harvest agricultural machinery, wet grain cleaning, transportation, bin before(after) drying, automation and control systems to dust settling system.

Monday, March 10, 2014

Muyang Grain Storage System

Muyang offers products and complete solutions in the field of grain handling, cleaning, drying and storage for agribusiness section. There are now over 1000 Muyang storage silo projects standing around the world and making their efforts to the global food security, from grain collection points to grain elevators, from inland/water terminals to processing plants such as feed mills, rice mills, flour mills, breweries, oilseed processing factories, etc. The key products and systems include:

Assembly type steel silos, 1~18,000 t/silo;

Spiral steel silos, 1-8,000 t/silo;

Material handling system: bucket elevators, conveyors, sweepers, spreaders, etc.;

Conditioning and drying systems: cleaners, dust collectors, dumping systems, dryers, fans, controls, etc.

Assembly type steel silos, 1~18,000 t/silo;

Spiral steel silos, 1-8,000 t/silo;

Material handling system: bucket elevators, conveyors, sweepers, spreaders, etc.;

Conditioning and drying systems: cleaners, dust collectors, dumping systems, dryers, fans, controls, etc.

Thursday, January 16, 2014

Muyang Steel Silo Engineering

Muyang is a nationally recognized leader in the design and construction of reinforced steel silos. Muyang prefabricated corrugated steel silo using a full U.S. latest manufacturing technology and equipment, equipped with the most advanced computer system that provides users with 10 to 16,800 tons of different models of flat, conical bottom, fluidizing material and porous material discharging, its unique in China.

The steel silo is for anchoring on a concrete foundation or steel structure with an extensive range of accessories. And one single-silo capacity is up to 18,000 tons with comprehensive configurations to meet customers' different requirements. We are able to examinate any bulk material in our laboratories and Technology Center with standardized range of accessories.

Optimum workmanship - no corners and edges on grain storage silo inside, high-quality surfaces, low-scratch method used for shaping and certified welding quality. We design our silos as per your individual requirements. It is suitable for bulk solid materials with good and poor flowability (plastic powders, recycled material, pellets, and flowable elastomers).

Muyang is the world's leading overall storage facilities and engineering solutions provider, in addition to providing storage silo, spiral silo and insulation silo, but also providing a comprehensive package of equipment and systems, including transportation equipment, drying equipment, as well as providing the overall design, construction , integration services.

The steel silo is for anchoring on a concrete foundation or steel structure with an extensive range of accessories. And one single-silo capacity is up to 18,000 tons with comprehensive configurations to meet customers' different requirements. We are able to examinate any bulk material in our laboratories and Technology Center with standardized range of accessories.

Optimum workmanship - no corners and edges on grain storage silo inside, high-quality surfaces, low-scratch method used for shaping and certified welding quality. We design our silos as per your individual requirements. It is suitable for bulk solid materials with good and poor flowability (plastic powders, recycled material, pellets, and flowable elastomers).

Muyang is the world's leading overall storage facilities and engineering solutions provider, in addition to providing storage silo, spiral silo and insulation silo, but also providing a comprehensive package of equipment and systems, including transportation equipment, drying equipment, as well as providing the overall design, construction , integration services.

Thursday, January 2, 2014

How to Choose the Suitable Storage Silo for the Grain

Silos are commonly used to store bulk materials. Grain storage silo is used in agriculture to store grain or fermented feed commonly known as silage. Before investing in grain silo you may want to know more about them.

Why do we need grain silo?

It is very important to keep the grains market-ready for sale. The grains should be kept dry. Storage bin should facilitate easy handling of the grains. Steel silo is meant to store grains safely so that you get a good return for the money invested. There are simple bins with a single auger to dry the grains and large complicated ones that are equipped with sophisticated mechanisms to handle and dry the grains.

Before investing in silo you must be aware of the choices available to you.

How to select the best grain silo?

Getting grain silo is a matter of huge investment. You must make sure that the investment you make gives you good return. The storage silo you built must last long and provide all the benefits you have been looking for. When it comes to choosing the material for silo you have a lot of options.

Generally the grain silo is built from metals, cement and bricks. Storing grains in metal silo is very common. You will find silo made from galvanized metal and smooth metal. But these are susceptible to rust and may not be safe for your grains. You cannot increase the capacity also when you have the need.

Why do we need grain silo?

It is very important to keep the grains market-ready for sale. The grains should be kept dry. Storage bin should facilitate easy handling of the grains. Steel silo is meant to store grains safely so that you get a good return for the money invested. There are simple bins with a single auger to dry the grains and large complicated ones that are equipped with sophisticated mechanisms to handle and dry the grains.

Before investing in silo you must be aware of the choices available to you.

How to select the best grain silo?

Getting grain silo is a matter of huge investment. You must make sure that the investment you make gives you good return. The storage silo you built must last long and provide all the benefits you have been looking for. When it comes to choosing the material for silo you have a lot of options.

Generally the grain silo is built from metals, cement and bricks. Storing grains in metal silo is very common. You will find silo made from galvanized metal and smooth metal. But these are susceptible to rust and may not be safe for your grains. You cannot increase the capacity also when you have the need.

Subscribe to:

Comments (Atom)